Kobayashi Groundbreaking Healthcare International facility. The 397,748-square-foot expansion facility will be built in Dalton, GA

American Fuji Seal

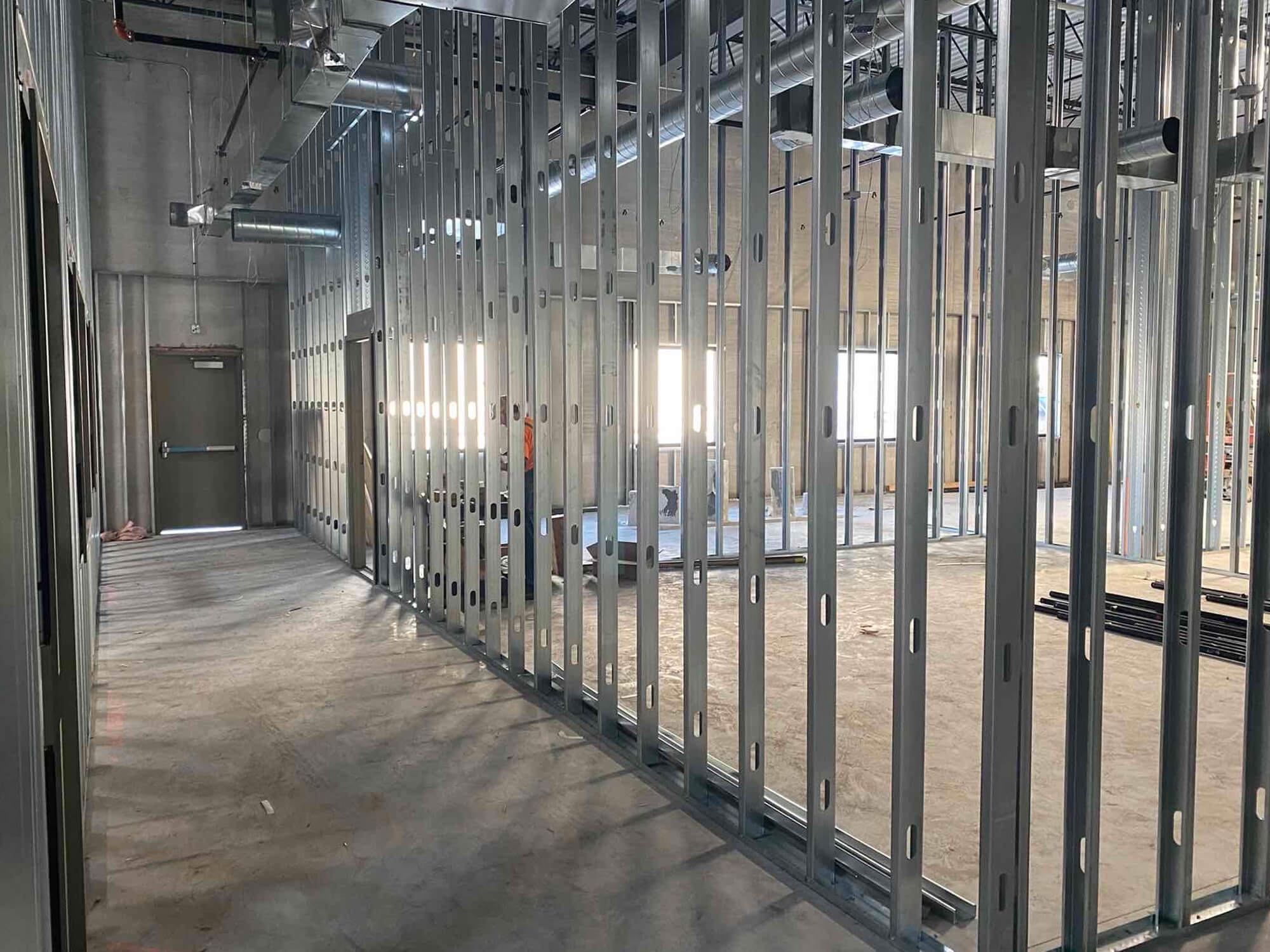

KBD Group provided Design-Build services for American Fuji Seal, a manufacturer of shrink-sleeve labels, self-adhesive labels, spouted pouches and packaging machinery. This manufacturing facility project involved 200,000 SF Tilt-up building with structural steel columns, joists and metal decking. Project also included a 60 Mil PVC roofing, some explosion relief panels, building plumbing, HVAC, and electrical.

JX USA Groundbreaking Ceremony

On October 5th, JX Nippon Mining and Metals USA, Inc. (JX USA) celebrated a groundbreaking event for the construction of their new state-of-the-art electronic materials manufacturing plant.

Trane Assembly Building

KBD Group provided design-build services for this 192,000 SF assembly building with 38 shipping and receiving docks that will produce Trane residential air conditioning units for Trane Technologies. The building has a connector corridor from new building to existing assembly plant.

Cargill Grain Transfer Facility

KBD Group provided Design-Build services for this barge transfer facility expansion on the Mississippi River.

![Project-Oceans-Ecopol-2[1]](https://kbd.group/wp-content/uploads/2023/07/Project-Oceans-Ecopol-21-768x768.jpg)

![Project-Oceans-Ecopol-2[1]](https://kbd.group/wp-content/uploads/2023/07/Project-Oceans-Ecopol-21-2-768x768.jpg)

![Project-Oceans-Ecopol-27[1]](https://kbd.group/wp-content/uploads/2023/07/Project-Oceans-Ecopol-271-768x768.jpg)

![Project-Oceans-Ecopol-36[1]](https://kbd.group/wp-content/uploads/2023/07/Project-Oceans-Ecopol-361-768x768.jpg)

![Project-Oceans-Ecopol-38[1]](https://kbd.group/wp-content/uploads/2023/07/Project-Oceans-Ecopol-381-768x768.jpg)